Monotube vs Twintube shocks

27th Dec 2022

Mono-tube or Twin-tube, which one is better for your application? That is a question that always comes up when picking the best shocks for your vehicle.

One thing is for sure, the difference in Mono vs Twin tube is the price. Twin-tube is budget friendly, and feels much more like a stock shock. A Mono-tube is designed for high performance driving, but gives you the ability to soften the shock.

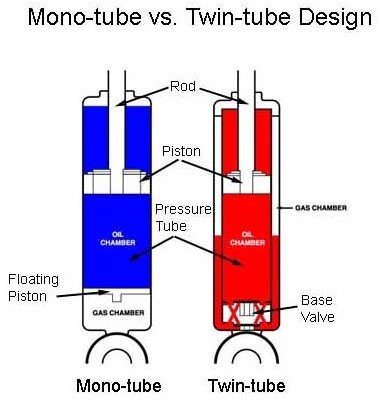

The image above is a good representation on the two styles. Mono is constructed with a single tube body and the Twin, well the name says it. Designed with twin tubes.

Mono-tube: the shell case itself works as a cylinder. The oil, gas chamber, piston valve and piston rod are all set inside that single tube. Mono-tube uses a free piston that completely separates the oil chamber from the gas chamber. The Mono style will handle faster strokes with a higher heat rate.

Twin-tube: the Twin-tube has dual chambers in the shell case. The piston valve moves within the inner cylinder pushing oil through the outer chambers. The Gas chamber is also set in the outer shell chamber. Having a twin chamber gives the shock a more soft feel and will eat road bumps, but has a less performance affect at high speed racing. My best best is a Twin for street applications.

Pros and Cons on the two designs

Mono-tube Pros.

Oil damping can be generated continuously, because of the larger oil capacity and improved heat dissipation.

The larger sized piston valve creates a wider area to receive pressure, subtle damping force can be generated precisely.

Oil releases heat easier as the temperature increases. "Oxygenate" doesn't occur because, oil and gas are separated by a piston.

Mono-tube Cons.

High-pressure gas can lead to greater stress on seals.

Compared with the upright type, the inverted type tends to have more friction, because it has more moving parts.

Twin-tube Pros.

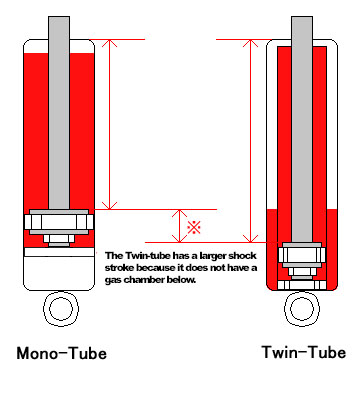

It is easier to secure sufficient stroke, because the oil and gas chambers are separated and not positioned above each other.

The use of base valve enables to keep gas pressure low, allowing for a more comfortable ride. Low gas pressure avoids stress on seals.

Even if the shell case is slightly damaged, the function of the shock absorber remains unaffected.

Standard manufacturing allows production costs low. Most brands are now Twin-tube.

Twin-tube Cons.

Oil capacity is not as large as the mono-tube. Stroke is lower.

Size of the piston valve is not as large as the mono-tube, rebound is slower.

The structure restricts installation angles. Cant put the shock in a high rate of Camber angle.

The oil and gas chambers are not separated, so there is a possibility of oil and gas mixture.

A race shock absorber designed for flat circuits does not require as much of a stroke as a Twin-tube street shock absorber, which always has to deal with uneven street surfaces, and other conditions.

So which shock is better? The answer is depending on how the vehicle will be used.

Since the Mono-tube design can handle higher heat due to its shock body shell design and oil fluids, going to a track event and pushing the car will not be an issue. The Twin-tube shell body will not allow high heat strokes and can cause the oil and gas mixtures to turn to slush.

We are sure that a Mono-tube design is good for street condition with an occasional track event or back road runs, but if comfort is on your mind, we suggest a Twin-tube, plus it cost less.

Any questions regarding the GAB Suspension products, please email us. We love to help with your investments.